-

- TDS

- What is TDS

TDS

What is TDS

Introduction

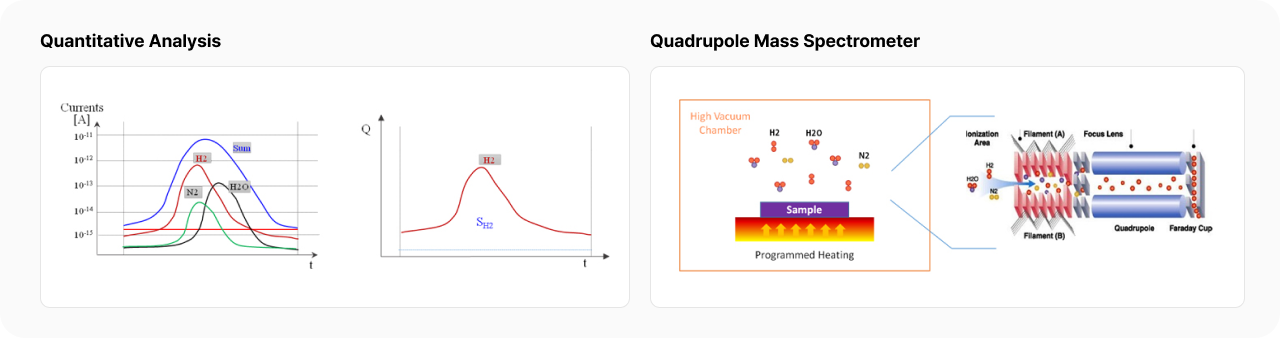

TDS stands for Thermal Desorption Spectroscopy, a device used to measure and analyze gases desorbed from the surface of a sample as its temperature is increased.

This method provides precise information about the binding energy of each molecule.

Utilizing this technology enables the detection of changes in the quantity and composition of gases to trace amounts in ultra-high vacuum conditions, allowing for both qualitative and quantitative measurement of changes over time and temperature.

Among analytical techniques, TDS is notable for its high sensitivity and stability without the need for chemicals.

What is TDS?

TDS is a device used to measure and analyze gases that are desorbed from the surface of a sample as its temperature is increased.

It is employed to perform qualitative and quantitative analyses of gases emitted during processes, allowing for the early detection and prevention of issues by analyzing their causes.

Why TDS?

Simple Idea : Adsorbed particles with different binding energies will desorb at different temperature.

Applications

- - Semiconductor and Display Material Analysis

- - Hydrogen Analysis in Automotive and Steel Materials

- - Ultra-Pure Material and Trace Analysis

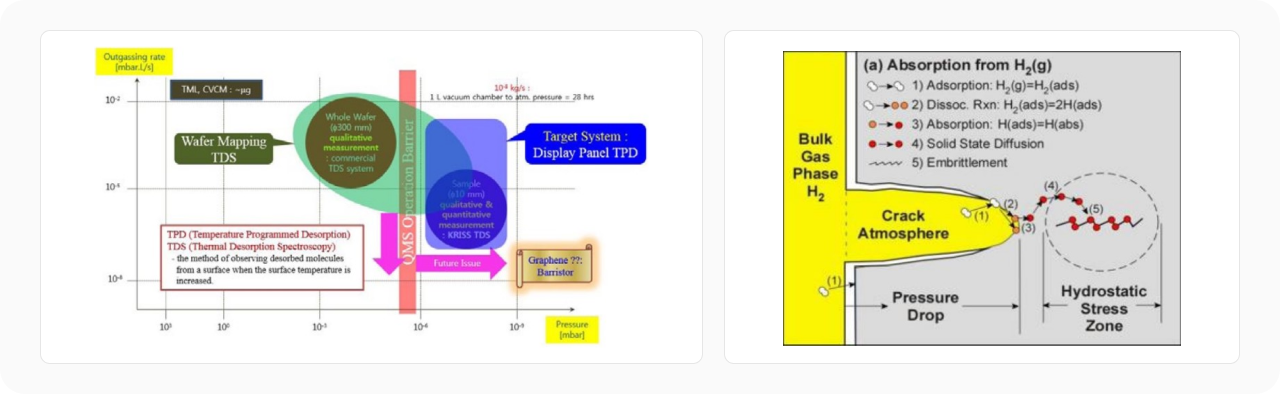

The technique of examining impurities (outgassing rate) based on temperature elevation typically employs the TDS method. However, to date, there has not been a well-established method for local and directional real-time impurity mapping on wafers, and systems capable of conducting both qualitative and quantitative analyses simultaneously are virtually non-existent. Our company provides a TDS system that overcomes these limitations.

Performance Comparisions

IVT's TDS system boasts competitive advantages such as calibration, heating, and pumping speed over those of other companies.

Additionally, depending on the application area, we offer user-friendly DAQ (Data Acquisition) software.

| fTDS(Fusion)&TVGA | IVT sTDS(smal) | mTDS(moduated) | Company A | Company B | tTDS(throughput) | |

|---|---|---|---|---|---|---|

| Measurement Method | Throughtput⑴ mapping capability | Throughtput⑴ | Modulation⑴ | QMS signal⑵ | QMS signal⑵ | Throughtput⑴ |

| Calibration | O: direct KRISS measurement traceability | O: direct KRISS measurement traceability | O: direct KRISS measurement traceability | Δ indirect traceability, standard sample required | Δ indirect traceability, standard sample required | O: direct NMI measurement traceability |

| Sample | 300mm wafer, Ø60mm | Ø20mm Sample | Ø20mm Sample | Ø10mm Sample | Ø10mm Sample | Ø10mm Sample |

| Heater | Beam heater Lamp heater | IR rod heater | IR rod heater | IR rod heater | Furnace : PID Difficult | IR rod heater |

| Hydrogen Pumping Speedr | Method 1 : not enough calibration only Method 2 : enough | Method 1 : not enough calibration only Method 2 : enough | Variable : dependent on the Position of the Orifice Plunger | Enough | Not enough : buffer zone (two TMPs Required) | Not enough : fixed orifice constraint |

| AnyMolecule, X | Easy : direct measurement | Easy : direct measurement | Difficult | Indefinite Traceability QMS Dependent Signal | Indefinite Traceability, QMS Dependent Signal | Modification required |

| Atomic Mass | 200 | 200 | 200 | 200 | 200 | 200 |

| Uncerainty | 18.0%(BPG 400 IG) | 4.8% or 18.0% | Conductance Dependent | Unknown | Unknown | 4.8% (370 Stavil IG) |

| DAQ Software | Real Time | Real Time (user specitied) | Not Real Time | Real Time | Real Time | Real Time |

| Maintenance | Easy | Easy | Easy | Very Difficult | Very Difficult | Easy |

| Competitiveness | Most Competitive | Highly Competitive | Competitive | Highly Competitive | Very Competitive | Very Competitive |

(1) P.A.Redhead, “Recommended practices for measuring and reporting outgassing data”, J.Vac.Sci. Technol.A 20(5). Sep/Oct 2002

(2) US 5,528,032(June18,1996) - Thermal Desorption Gas Spectrometer, ESCO Ltd.